G6 Tolerance Chart - Fitting with a narrow gap so as to. Find the size limits and deviations for shafts and holes with g (g) tolerance classes according to iso 286. Determine plus and minus tolerance for the specific iso 286 shaft tolerance data calculator Compare the values in millimeters and. It provides a system of tolerances and deviations suitable for two types of feature: The following defines the preferred tolerance basis for hole and shaft per. “cylinder” and “two parallel opposite surfaces”. This web page provides a table of metric shaft tolerances based on iso 286 standards and a calculator to find the plus and minus tolerance. Fine roll fit g5 g6 continuously revolving part of a precision machine under a light load.

39 Reading Chart 25 H7 g6 YouTube

Compare the values in millimeters and. The following defines the preferred tolerance basis for hole and shaft per. “cylinder” and “two parallel opposite surfaces”. Find the size limits and deviations for shafts and holes with g (g) tolerance classes according to iso 286. Fine roll fit g5 g6 continuously revolving part of a precision machine under a light load.

Limit, Fit And Tolerance (मराठी मध्ये) 39. Reading standard chart 25 H7 g6

Determine plus and minus tolerance for the specific iso 286 shaft tolerance data calculator Compare the values in millimeters and. Fitting with a narrow gap so as to. It provides a system of tolerances and deviations suitable for two types of feature: Fine roll fit g5 g6 continuously revolving part of a precision machine under a light load.

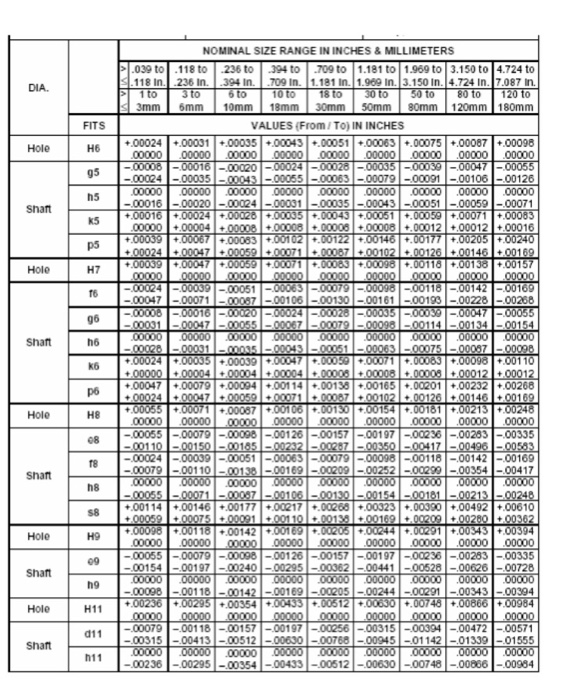

ENGR1304 Chapter 7 Tolerances

Fine roll fit g5 g6 continuously revolving part of a precision machine under a light load. Compare the values in millimeters and. Determine plus and minus tolerance for the specific iso 286 shaft tolerance data calculator “cylinder” and “two parallel opposite surfaces”. The following defines the preferred tolerance basis for hole and shaft per.

Guidelines for Shaft and Bore Tolerances Encoder Product Company

Fitting with a narrow gap so as to. “cylinder” and “two parallel opposite surfaces”. The following defines the preferred tolerance basis for hole and shaft per. Compare the values in millimeters and. It provides a system of tolerances and deviations suitable for two types of feature:

Basic tolerances and tolerance fields

Fine roll fit g5 g6 continuously revolving part of a precision machine under a light load. It provides a system of tolerances and deviations suitable for two types of feature: Find the size limits and deviations for shafts and holes with g (g) tolerance classes according to iso 286. The following defines the preferred tolerance basis for hole and shaft.

Solved Q3Calculate the following for an H7/g6 type ISO fit

Compare the values in millimeters and. This web page provides a table of metric shaft tolerances based on iso 286 standards and a calculator to find the plus and minus tolerance. The following defines the preferred tolerance basis for hole and shaft per. “cylinder” and “two parallel opposite surfaces”. Fitting with a narrow gap so as to.

Rods Precision, g6/h7 Tolerance, 1045 Carbon Steel, 303/304 Stainless

Compare the values in millimeters and. It provides a system of tolerances and deviations suitable for two types of feature: Fitting with a narrow gap so as to. This web page provides a table of metric shaft tolerances based on iso 286 standards and a calculator to find the plus and minus tolerance. The following defines the preferred tolerance basis.

G6 Iso Tolerances My XXX Hot Girl

Fine roll fit g5 g6 continuously revolving part of a precision machine under a light load. Determine plus and minus tolerance for the specific iso 286 shaft tolerance data calculator “cylinder” and “two parallel opposite surfaces”. Fitting with a narrow gap so as to. The following defines the preferred tolerance basis for hole and shaft per.

Limit, Fit And Tolerance (मराठी मध्ये) 39. Reading standard chart 25 H7 g6

It provides a system of tolerances and deviations suitable for two types of feature: Fitting with a narrow gap so as to. Compare the values in millimeters and. This web page provides a table of metric shaft tolerances based on iso 286 standards and a calculator to find the plus and minus tolerance. “cylinder” and “two parallel opposite surfaces”.

Shaft Tolerance Table (Iso) ≥ < c9 d8 e7 e8 f7 g6 h5 h6 h7 h8 js6 js7

Compare the values in millimeters and. Fitting with a narrow gap so as to. Determine plus and minus tolerance for the specific iso 286 shaft tolerance data calculator “cylinder” and “two parallel opposite surfaces”. Fine roll fit g5 g6 continuously revolving part of a precision machine under a light load.

Determine plus and minus tolerance for the specific iso 286 shaft tolerance data calculator It provides a system of tolerances and deviations suitable for two types of feature: Fine roll fit g5 g6 continuously revolving part of a precision machine under a light load. Compare the values in millimeters and. Find the size limits and deviations for shafts and holes with g (g) tolerance classes according to iso 286. This web page provides a table of metric shaft tolerances based on iso 286 standards and a calculator to find the plus and minus tolerance. The following defines the preferred tolerance basis for hole and shaft per. “cylinder” and “two parallel opposite surfaces”. Fitting with a narrow gap so as to.

Compare The Values In Millimeters And.

This web page provides a table of metric shaft tolerances based on iso 286 standards and a calculator to find the plus and minus tolerance. Determine plus and minus tolerance for the specific iso 286 shaft tolerance data calculator “cylinder” and “two parallel opposite surfaces”. Find the size limits and deviations for shafts and holes with g (g) tolerance classes according to iso 286.

Fine Roll Fit G5 G6 Continuously Revolving Part Of A Precision Machine Under A Light Load.

The following defines the preferred tolerance basis for hole and shaft per. It provides a system of tolerances and deviations suitable for two types of feature: Fitting with a narrow gap so as to.